Fire smoke exhaust systems are not merely a legal requirement but a critical component of fire protection and firefighting (PCCC) strategies in all modern buildings, from industrial plants to high-rise skyscrapers. The primary function of these systems is to control and remove hazardous by-products of fire—mainly smoke, toxic gases, and high temperatures—to protect human life and preserve building structures.

I. Technical Operating Principles of Fire Smoke Exhaust Systems

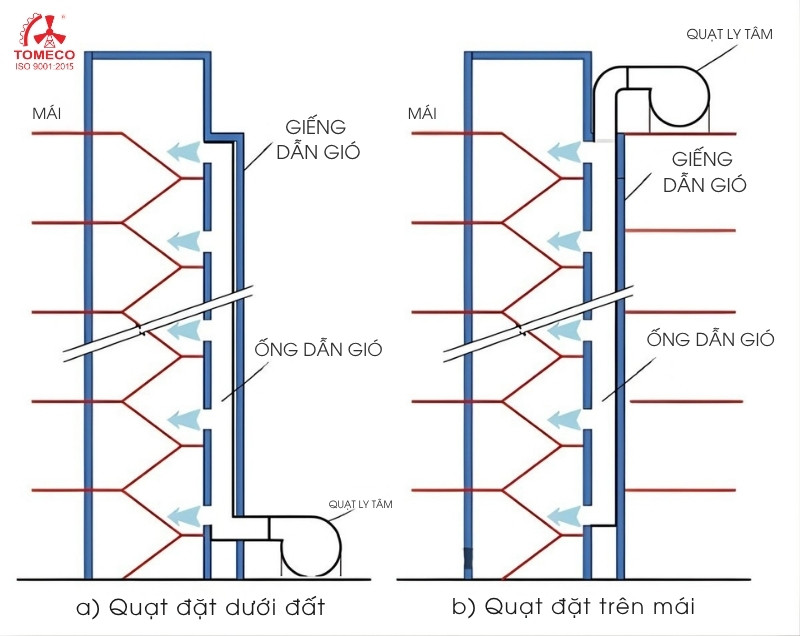

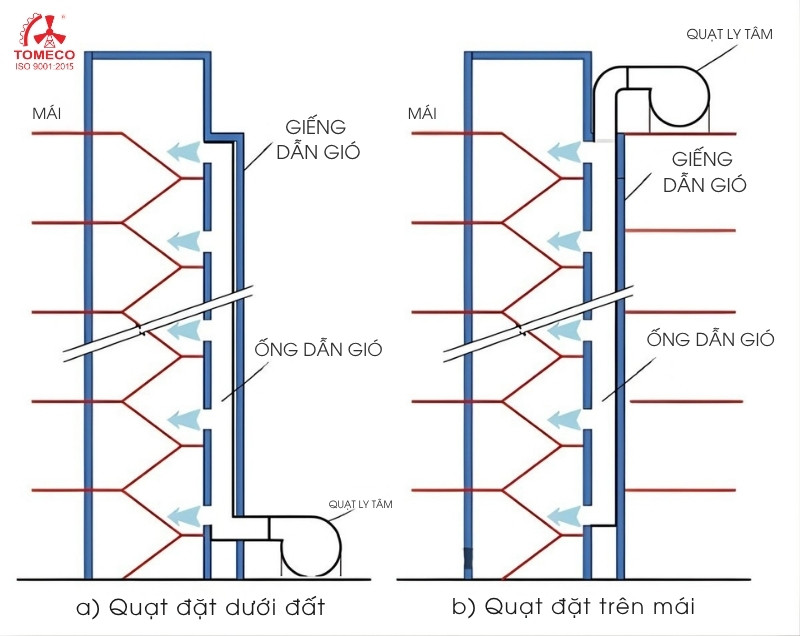

The operation of a fire smoke exhaust system is based on creating pressure differentials and controlling airflow. The system is activated automatically or semi-automatically upon receiving a fire alarm signal.

- Detection and Activation: Fire incidents are detected by smoke detectors and heat detectors. The fire alarm control panel then sends activation signals to start the smoke exhaust fans and open fire dampers within the ductwork system.

- Smoke Extraction: Industrial fire smoke exhaust fans operate to remove smoke and hot gases from the fire zone, reducing toxic gas concentration and improving visibility for evacuation and firefighting operations.

- Pressurization: The system is typically integrated with stairwell pressurization fans to create positive pressure, preventing smoke from entering escape routes and providing safer conditions for occupants and rescue forces.

II. Mandatory Technical Standards for Fire Smoke Exhaust Fans

To ensure reliable operation under extreme fire conditions, industrial fire smoke exhaust fans must comply with strict technical standards:

| Technical Criteria | Key Requirements | Critical Importance |

| Heat Resistance | Stable operation at 300°C for at least 2 hours | Ensures continuous operation throughout rescue and firefighting activities |

| Operating Performance | High airflow capacity and sufficient pressure | High airflow replaces contaminated air; high pressure overcomes duct resistance |

| Construction Materials | Heat-resistant steel housing and impellers, corrosion-resistant, fireproof coating | Prevents deformation under high temperatures and extends equipment lifespan |

| Automation & Power Supply | Compatible with central fire alarm systems and equipped with backup power | Ensures uninterrupted operation even during power outages |

III. Classification and Specialized Applications of Smoke Exhaust Fans

Selecting the appropriate fan type is a decisive factor in the effectiveness of a fire smoke exhaust system.

1. Axial Flow Fan

- Operating principle: Airflow moves parallel to the fan axis

- Characteristics: High airflow rate, effective in straight ducts and large open spaces

- Technical applications: Smoke extraction in corridors, basements, industrial workshops

- Fire-rated design: Motor separated from airflow or designed to withstand 300°C for 2 hours

2. Centrifugal Fan

- Operating principle: Air enters at the center and exits perpendicular to the rotation axis

- Characteristics: High static pressure, suitable for duct systems with multiple bends

- Technical applications: Complex basements, escape stairwells, pressurization zones

- Operating modes: Dual-speed operation—low speed for daily ventilation, high speed for emergency smoke extraction

TOMECO – A Trusted Partner for Fire Smoke Exhaust Systems

With more than 32 years of experience in industrial fan manufacturing, TOMECO is a leading provider of fire smoke exhaust solutions in Vietnam. TOMECO delivers comprehensive fire smoke exhaust systems that are efficient, durable, and fully compliant with regulations.

- Certified products: A wide range of models rigorously tested and quality-certified

- Professional consulting: Experienced engineers provide optimal solutions for fan type selection, capacity, positioning, and system design

- End-to-end technical support: From site survey, design, installation, commissioning, to maintenance

Choosing TOMECO means choosing quality, safety, and industry-leading reliability in Vietnam’s industrial fan sector.

Tiếng Việt

Tiếng Việt English

English