At a leading Japanese-invested waste-to-energy plant in Northern Vietnam, the imported fly ash screw conveyor system failed prematurely, causing costly downtime. With deep expertise in handling abrasive materials, TOMECO provided a custom-engineered solution that restored operations, optimized efficiency, and minimized maintenance.

Field Challenge: Wet Fly Ash – Rapid Wear – Production Halt

At a waste-to-energy plant project in Northern Vietnam, a Japanese FDI enterprise – a provider of integrated systems for the recycling and energy sectors – faced serious challenges when its imported Fly Ash Conveyor of the Kneading Machine type suffered severe wear and tear after only a short period of operation.

The root cause was wet fly ash – a material with high adhesiveness that hardens like cement once dried. Under continuous friction with the screw blades, this material rapidly wore down their surfaces. By the time TOMECO conducted its on-site inspection, the blades had been almost completely eroded and could no longer transport the material. The client required a highly durable, stable solution with minimal maintenance needs – something that standard imported equipment could not deliver.

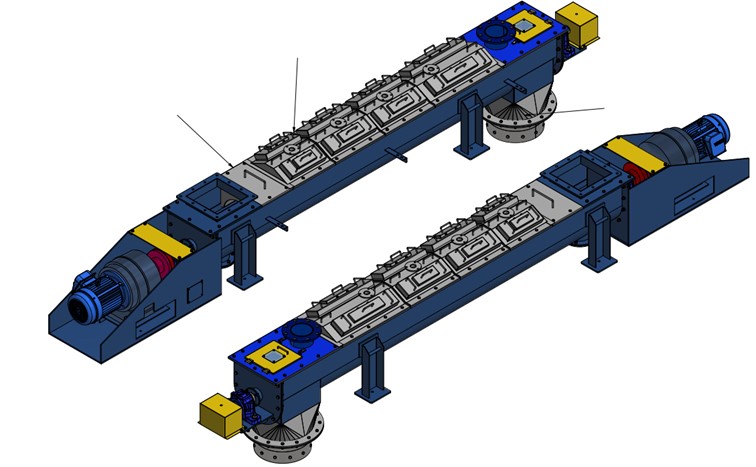

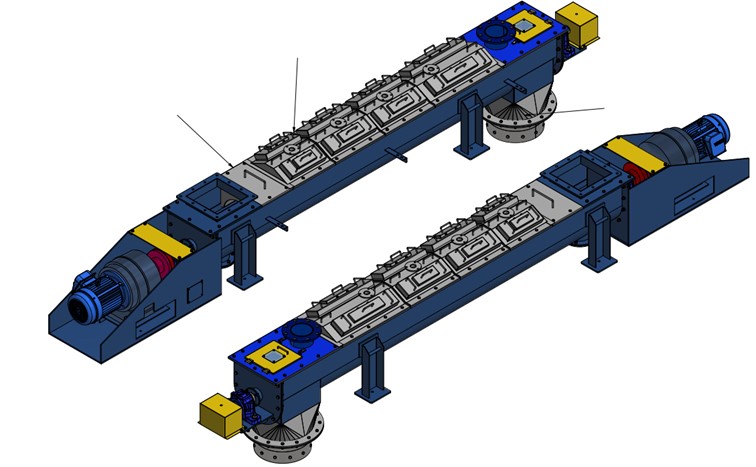

Customized Solution from TOMECO: Redesign from the Ground Up, Optimize Every Detail

Upon receiving the challenge, TOMECO’s engineering team quickly initiated a comprehensive technical consulting process:

1. Redesigning the Screw Conveyor Structure

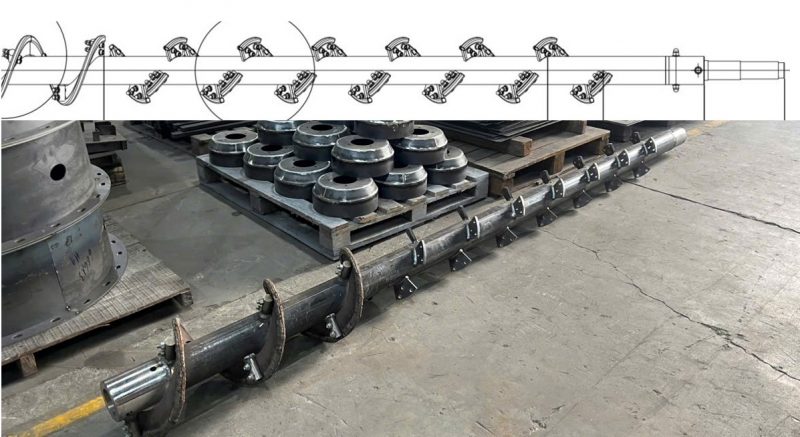

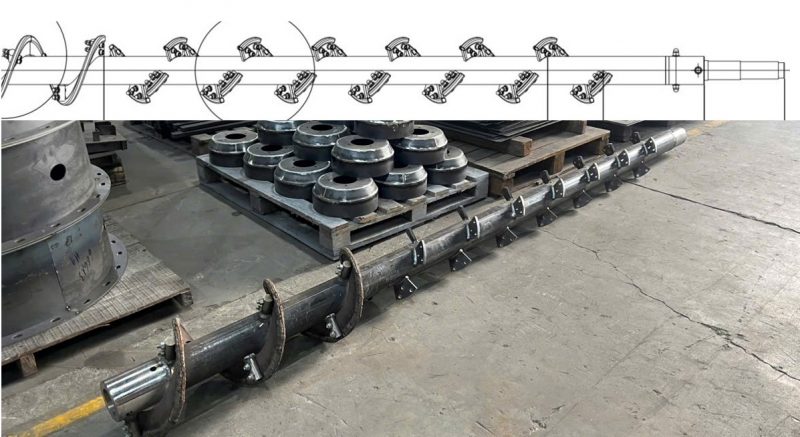

Recalculated screw pitch to regulate material flow and reduce concentrated wear points.

Converted from a one-piece design to a modular structure with detachable components, enabling flexible maintenance without disrupting the entire production line.

2. Selecting High Wear-Resistant Materials

Leveraging experience from the cement and metallurgical industries, TOMECO selected high-hardness, wear-resistant materials.

Applied special overlay welding at the screw blade tips—the most abrasion-intensive zones—to extend operational lifespan.

3. Simulation and Technical Validation

- Used CFD simulation tools to analyze stress and material flow, ensuring optimal performance under actual operating conditions.

- Provided full, transparent technical documentation, making it easy for the client to review and approve.

The entire process, from field survey to installation, was completed within just two months—demonstrating TOMECO’s strong capability in technology mastery and rapid, efficient production execution.

Results: Stable Operation with Minimal Maintenance

The new screw conveyor supplied by TOMECO has since operated continuously and stably at the waste-to-energy plant, with zero technical failures. Blade wear was eliminated, preventing unplanned shutdowns.

The client highly appreciated that TOMECO was not just an equipment supplier but a true technical partner—accompanying them from survey to design and implementation with a tailored solution that optimized operations while reducing maintenance costs to nearly zero.

TOMECO – Trusted OEM Partner for FDI Enterprises in Vietnam

The success of this project is clear proof of TOMECO’s capability in solving complex technical challenges, particularly under harsh operating conditions. With a fully integrated value chain—from consulting, design, and material selection to manufacturing and installation—TOMECO continues to strengthen its role as a strategic partner for FDI enterprises in the fields of energy, recycling, chemicals, and environmental treatment in Vietnam.

📞 Contact TOMECO for customized screw conveyor solutions or other industrial mechanical equipment tailored to your project.

➡ Technical Hotline: 0945 823 789

➡ Email: toancau@tomeco.vn

🌐 Website: https://tomeco.vn/

📢 Facebook: https://www.facebook.com/tomeco.vietnam

🎬 Youtube: https://www.youtube.com/@quatcongnghieptomeco2331

📣 LinkedIn: https://www.linkedin.com/company/tomeco-mechanic-electrical-join-stock-company

Tiếng Việt

Tiếng Việt English

English