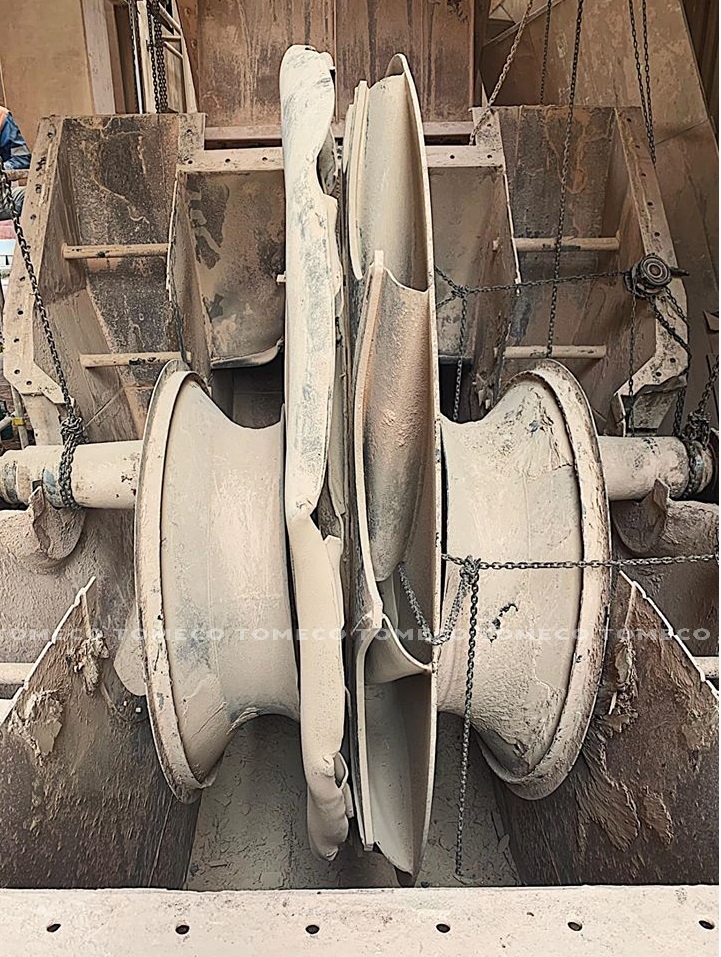

At one of Vietnam’s largest cement plants, a massive 3000mm-diameter centrifugal fan impeller was completely destroyed in a sudden breakdown. The entire production line came to a halt, threatening enormous economic losses. The plant’s management urgently needed a solution: the impeller had to be restored as quickly as possible to bring the system back to life.

And TOMECO Service answered the call.

With nearly three decades of experience serving the cement industry, TOMECO has the proven capability to design and manufacture fans of any size to precise technical standards. Over the years, our teams have “rescued” countless plants by restoring impellers ranging from 400mm to 4000mm in diameter – and this mission was no exception.

A Race Against Time

The moment the request came in, TOMECO activated emergency response mode. Our sole mission: to deliver speed without compromise on quality.

Within just 12 hours, we had launched parallel work streams:

Conducting surveys and creating a detailed 3D design.

Gathering operational data and identifying root causes.

Selecting the most suitable materials.

Finalizing quotations and contracts.

Preparing all supplies and tooling for production.

From there, our expert workforce pushed forward, working around the clock under strict international standards (ISO 9001, ISO 45001, ISO 14001).

In less than 72 hours – after days and nights of relentless effort – TOMECO successfully restored the impeller. It is now ready to be installed, ensuring the cement plant can resume operations with minimal downtime and minimal financial loss.

This achievement was more than just a technical success: it was a mission accomplished for our client’s peace of mind and prosperity.

At TOMECO, we are always ready to take on even tougher rescue missions – because our customer’s success is our highest priority.

Tiếng Việt

Tiếng Việt English

English