A detailed guide on how to install inline cabinet fans correctly, ensuring smooth operation, noise reduction, energy efficiency, and optimal ventilation performance.

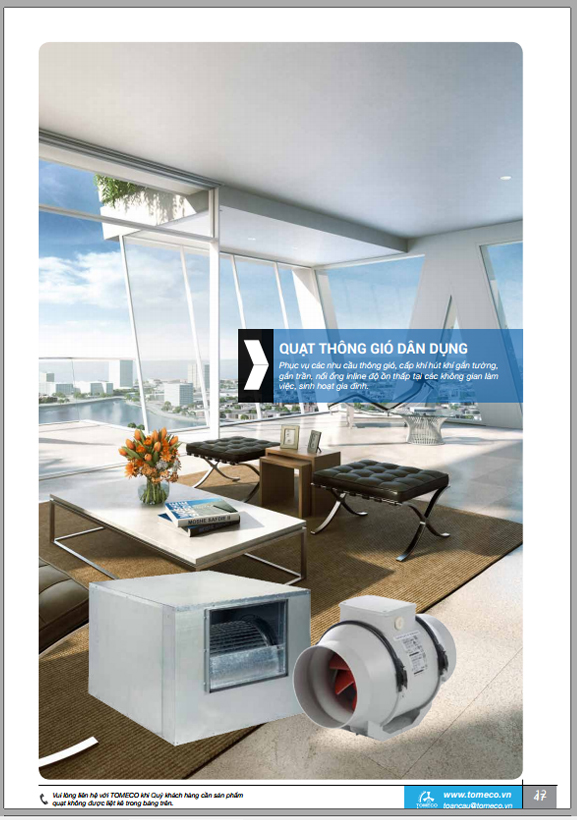

I. Introduction to Inline Cabinet Fans

Inline cabinet fans are concealed ceiling-mounted ventilation devices widely used in offices, restaurants, shopping malls, and industrial facilities. Their key advantages include compact design, easy concealment within ceiling spaces, quiet operation, and strong static pressure, enabling uniform airflow throughout duct systems.

However, to ensure stable operation, long service life, and effective noise reduction, proper installation is mandatory. Below is a step-by-step installation guide developed by TOMECO engineers.

II. Pre-Installation Preparation

1. Equipment and accessory inspection

Before installation, verify:

Fan model and airflow direction (intake / exhaust)

Rated power and voltage

Included accessories: duct flanges, mounting brackets, anti-vibration rubber pads, electrical cables, and backdraft damper (if required)

2. Installation location preparation

Select a position close to the main duct line for convenient connection and maintenance

If installed above a suspended ceiling (gypsum ceiling), reinforce the mounting frame with steel or aluminum to ensure sufficient load capacity

Maintain a minimum clearance of 300 mm between the fan and ceiling to allow maintenance access

3. Required tools

Wrenches, screwdrivers, electric drill, spirit level, measuring tape, angle square

Acoustic insulation materials, electrical insulation tape, safety gloves, and protective goggles

III. Inline Cabinet Fan Installation Procedure

Step 1: Determine airflow direction

Identify the intake and discharge directions based on the arrow marked on the fan casing

The intake side connects to exhaust air or indoor air ducts, while the discharge side directs air outdoors or to fresh air supply zones

Step 2: Secure the mounting frame and fan position

Use dedicated mounting brackets or stainless-steel straps to secure the fan

Install anti-vibration rubber pads at contact points to minimize noise and vibration

Ensure the fan is horizontally level using a spirit level

Step 3: Connect to the duct system

Attach duct flanges to both fan ends using bolts, clamps, or airtight sealant

Ensure airtight duct connections to prevent static pressure loss

For systems with multiple bends, provide a straight duct section 3–5 duct diameters long before and after the fan to maintain airflow efficiency

Step 4: Electrical connection

Disconnect the power supply before wiring

Use cables with proper cross-sectional area and connect according to the manufacturer’s wiring diagram (typically shown on the fan label)

Properly connect the grounding wire (PE) to ensure electrical safety

Step 5: Operational testing

Run the fan under test load for 5–10 minutes

Check:

Correct airflow direction

Absence of abnormal vibration or noise

Stable current within rated limits

If equipped with a VFD or EC motor, adjust speed according to design requirements

IV. Technical Notes for Inline Cabinet Fan Installation

1. Avoid incorrect airflow direction

Incorrect intake/discharge orientation may reduce performance by 20–30% and generate excessive noise.

2. Vibration and noise control

Always use anti-vibration pads at mounting points

Apply acoustic insulation to the outlet duct to limit noise transmission

Avoid direct contact between the fan and ceiling structures

3. Electrical safety and maintenance

Install a dedicated circuit breaker (CB) for each fan

Clean fan impellers and filters (if any) every 3–6 months

Periodically inspect wiring, terminals, and grounding

V. Tips to Optimize Fan Performance and Service Life

Keep duct routes as short and straight as possible

Install backdraft dampers to prevent reverse airflow

Avoid operating fans in excessively humid environments or beyond design temperature limits

For kitchen exhaust or grease-laden environments, increase maintenance frequency to every 2–3 months

VI. Conclusion: Proper Installation – Quiet Operation – High Efficiency

Above is the standard inline cabinet fan installation guide from TOMECO experts. Proper installation ensures:

Maximum ventilation efficiency

Quiet, vibration-free operation

Reduced energy consumption and extended equipment lifespan

TOMECO recommends following these installation guidelines and using genuine accessories to ensure long-term safety, performance, and durability.

Frequently Asked Questions (FAQ)

1. What is the best installation location for an inline cabinet fan?

The fan should be installed near the center of the duct system to distribute airflow evenly. For concealed ceiling installation, the mounting frame must be reinforced to prevent vibration and noise.

2. Is a backdraft damper necessary?

Yes. A backdraft damper prevents reverse airflow and odor backflow when the fan is not operating, especially important for restaurants, industrial kitchens, and restrooms.

3. What is the recommended clearance between the fan and suspended ceiling?

A minimum clearance of 250–300 mm is recommended to allow heat dissipation and maintenance access.

4. Can inline cabinet fans be installed horizontally or vertically?

Yes. Inline cabinet fans can be installed horizontally or vertically depending on duct layout. For vertical installation, ensure reinforced mounting and proper anti-vibration supports.

5. How often should inline cabinet fans be cleaned and maintained?

Recommended maintenance intervals:

Offices, shopping malls: every 6 months

Restaurants, industrial kitchens: every 2–3 months

Cleaning includes impellers, filters, and motor inspection to maintain stable, quiet, and energy-efficient operation.

6. Do inline cabinet fans generate high noise levels?

No. TOMECO inline cabinet fans are designed with sound-insulated casings and centrifugal impellers, reducing noise by up to 15 dB(A) compared to conventional fans.

7. What electrical safety measures are required?

Always disconnect power before wiring

Use a dedicated circuit breaker

Proper grounding (PE) is mandatory

Use cables with correct cross-sectional area as specified by TOMECO

8. How can fan noise be further reduced?

Install anti-vibration rubber mounts

Apply acoustic insulation to outlet ducts

Maintain sufficient clearance from ceiling structures

Periodically check for loose bolts or impeller imbalance

==============

📞 Contact TOMECO for professional consultation, model selection, and project-specific installation guidance.

Northern Vietnam: +84 917 704 186

Southern Vietnam: +84 903 360 078

Technical Service: +84 977 246 853 | +84 945 823 789

Tiếng Việt

Tiếng Việt English

English