As factory digital transformation accelerates, industrial equipment increasingly requires accurate and continuous monitoring to ensure safe, stable operation and cost efficiency. For industrial fans – especially centrifugal fans, ID/FD fans, dust extraction fans, and high-temperature fans used in cement, metallurgy, chemical, and environmental industries—optimizing operational performance through digital technologies has become more critical than ever.

To address this demand, TOMECO has developed the TOMECO IoT System, a smart industrial fan monitoring solution that enables real-time equipment status tracking, early fault warnings, predictive maintenance, and energy optimization. The system is specifically designed for harsh operating environments in modern industrial plants.

1. Overview of the TOMECO IoT System

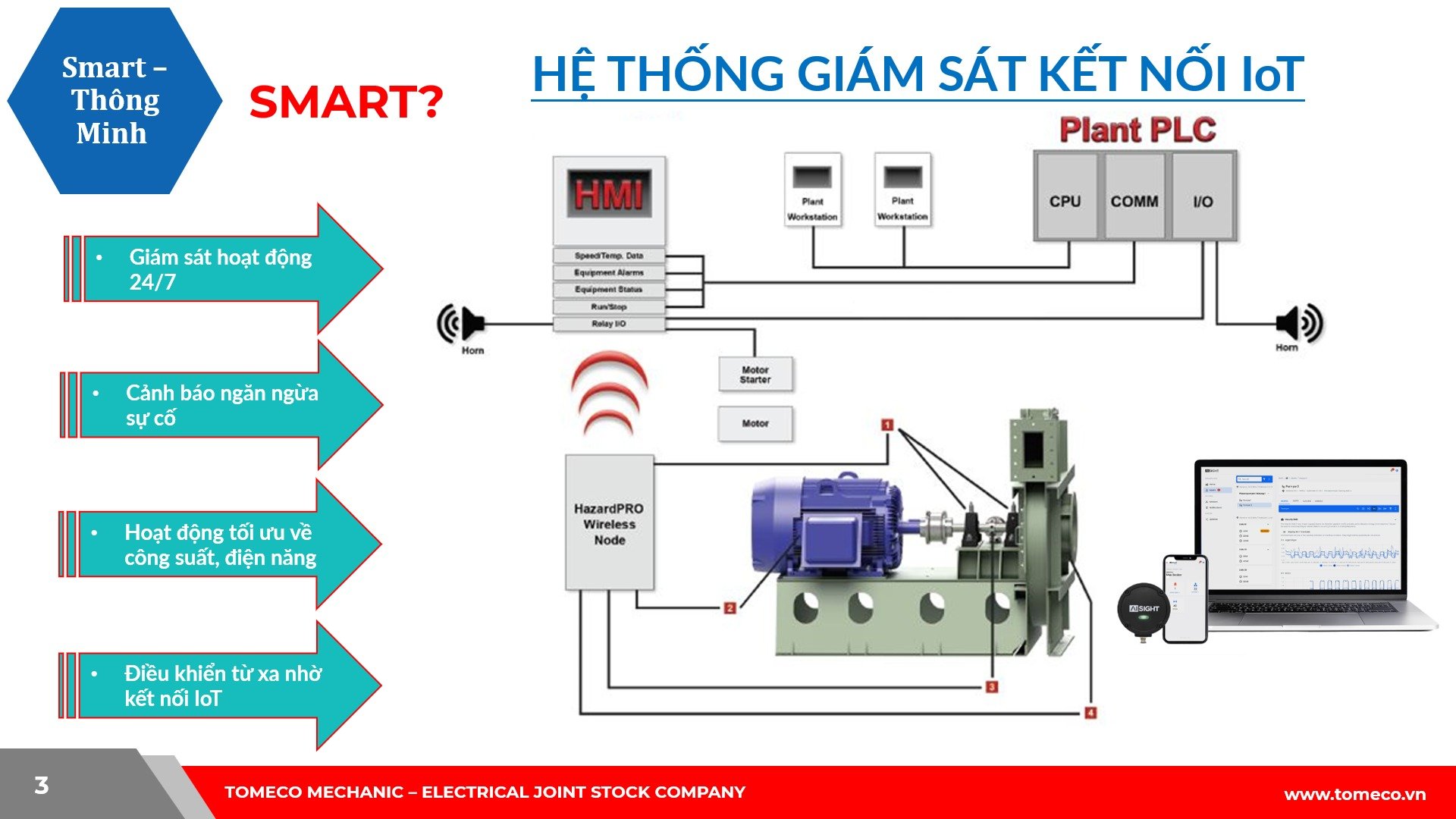

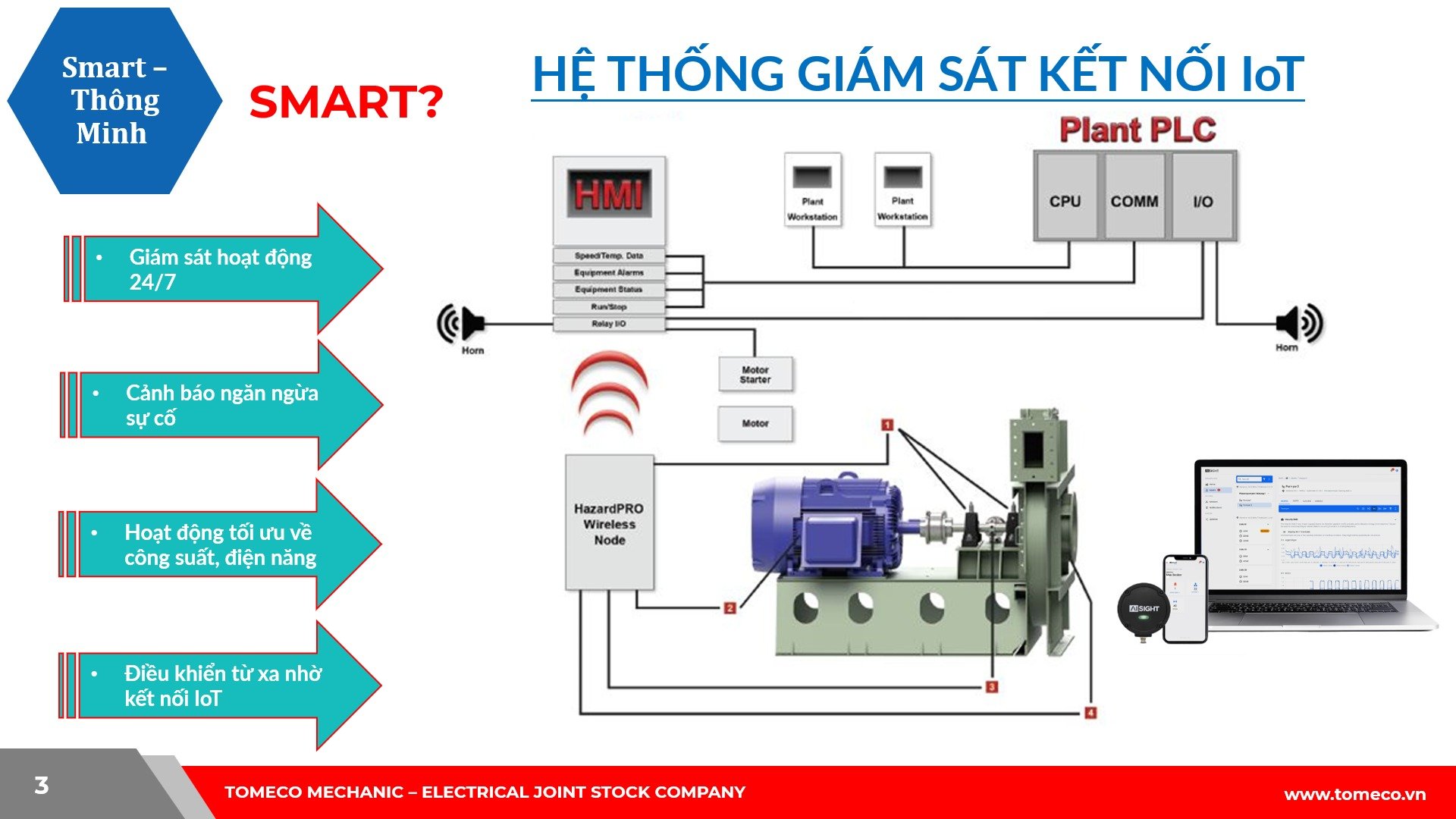

The TOMECO IoT System is developed as a comprehensive industrial IoT platform consisting of sensors, gateways, and data analytics software. The solution collects operational data from industrial fans, performs real-time analysis, and provides early alerts to operators.

System Architecture – Three-Layer Structure

1.1. Smart Sensor Layer (IoT Sensors)

Installed directly on industrial fans to collect key parameters, including:

Vibration → fan vibration monitoring

Bearing and motor temperature

Pressure and airflow

Voltage, current, and power consumption (IoT energy monitoring)

Rotational speed and transmission condition

1.2. Data Transmission Layer

Industrial IoT gateway

Communication protocols: MQTT / Modbus

Industrial WiFi / LAN / 4G connectivity

Stable data transmission to the TOMECO IoT Cloud

1.3. Monitoring & Analytics Layer

The TOMECO IoT Cloud software platform enables:

Remote fan monitoring via PC or mobile devices

Early alerts when abnormalities occur

Historical data storage and visualization

Performance comparison over time

Automatic technical report generation

2. Key Monitoring Parameters in the TOMECO IoT System

The system tracks three main groups of operational data:

2.1. Dynamic Monitoring

Shaft and bearing vibration

Abnormal rotor oscillation

Rotational speed

→ This is a critical foundation for predictive maintenance of industrial fans.

2.2. Mechanical Monitoring

Shaft misalignment

Bearing condition

Bearing temperature

Mechanical wear level

→ Particularly effective for IoT-enabled ID/FD fans and IoT dust extraction fans.

2.3. Energy Monitoring (IoT Energy Monitoring)

Voltage and current

Power consumption

Actual operating efficiency under load

→ Enables energy optimization and reduced operating costs for industrial fans.

3. Key Benefits of the TOMECO IoT System

3.1. Early Warning – Reduced Risk of Unexpected Downtime

Continuous data analysis triggers alerts when:

Vibration increases abnormally

Bearings overheat

Motors draw abnormal current

→ Reduces unexpected shutdown incidents by 70–90%.

3.2. Predictive Maintenance

Based on historical data, the system predicts optimal timing for:

Bearing replacement

Dynamic balancing

Shaft alignment inspection

→ Reduces annual maintenance costs by 20–40%.

3.3. Real-Time Energy Optimization

The system analyzes performance and recommends:

Variable speed drive (VSD) adjustments

Airflow regulation based on actual demand

→ Reduces industrial fan energy consumption by 15–30%.

3.4. 24/7 Smart Remote Monitoring

Through the TOMECO IoT Cloud, managers can monitor fan operation anytime, anywhere—especially valuable for plants with multiple workshops or production lines.

3.5. Extended Equipment Lifetime

Early detection of vibration, misalignment, and overheating helps significantly prolong fan service life.

4. Industrial Applications of the TOMECO IoT System

The TOMECO IoT System is compatible with most industrial fan types:

IoT dust extraction fans in wood processing and mineral industries

Smart industrial fans for metallurgy and steel plants

Thanks to its ability to operate under heavy load, high dust levels, and elevated temperatures, the system is particularly valuable for enterprises pursuing factory digital transformation and Smart Factory models.

A report by Hanoi Television about TOMECO’s IoT-based industrial fan management solution.

5. TOMECO – A Pioneer in Industrial Fan IoT Solutions in Vietnam

TOMECO holds a strong competitive advantage by combining:

Over 30 years of industrial fan manufacturing experience

Strong R&D capabilities

Sensors designed specifically for harsh industrial environments

Proprietary cloud software: TOMECO IoT Cloud

Proven deployment across numerous large-scale projects

TOMECO is currently one of the few companies in Vietnam that fully masters a specialized IoT solution dedicated to industrial fans—one of the most critical pieces of equipment in industrial plants.

6. Conclusion

The TOMECO IoT System not only helps enterprises reduce downtime risks, optimize energy consumption, extend equipment lifespan, and enable remote monitoring, but also represents a key step toward building:

Smart Factories

Predictive maintenance systems

Real-time production data management

TOMECO remains committed to continuous investment in industrial IoT technologies, delivering smart and efficient industrial fan monitoring solutions to customers in Vietnam and internationally.

Tiếng Việt

Tiếng Việt English

English