Introduction

-High temperature/fire is one of the most severe conditions to which structures can be subjected, and thus, the provision of appropriate safety measures for structural members is an important aspect of design and manufacturing.

-Heavy-duty fans and blowers are widely used in various industrial areas such as cement, ceramic tile, and chemical industries where they are operated at high temperature and dust laden gas flows.

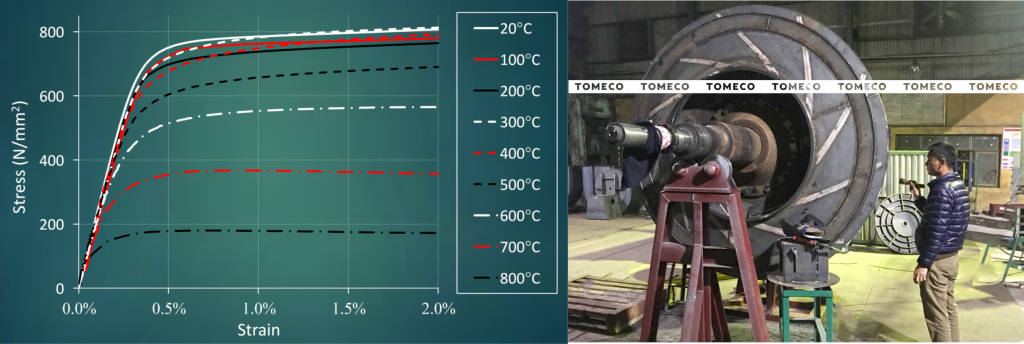

-Steel has excellent strength at ambient temperature, however, its mechanical behavior are often reduced with temperature. Thus, temperature dependent properties are considered to be important parameters in the selection of material of construction.

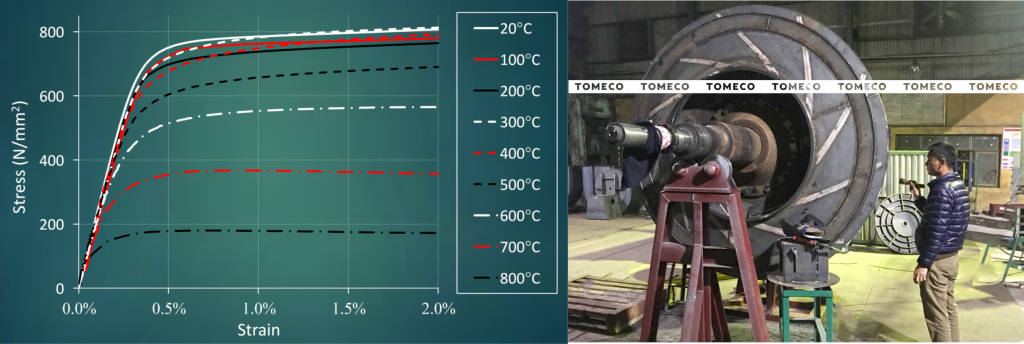

-In this work, thermal and mechanical behavior of high strength steel at elevated temperatures are analyzed for the restoration design and manufacturing of a centrifugal impeller in an induced draft fan at a cement plant. Successful restoration of the impeller is made based on the thermal stress study and FEA (Finite Element Analysis).

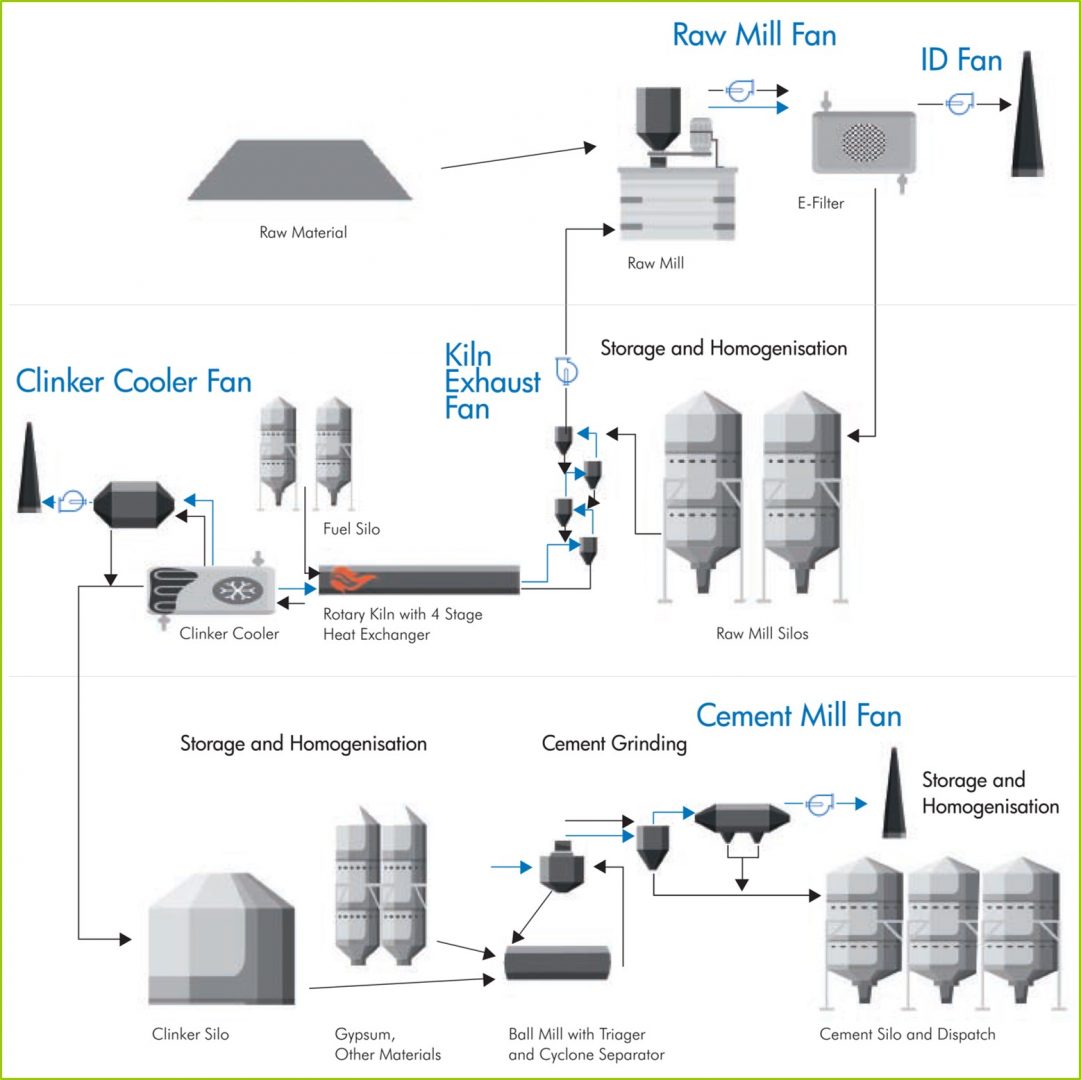

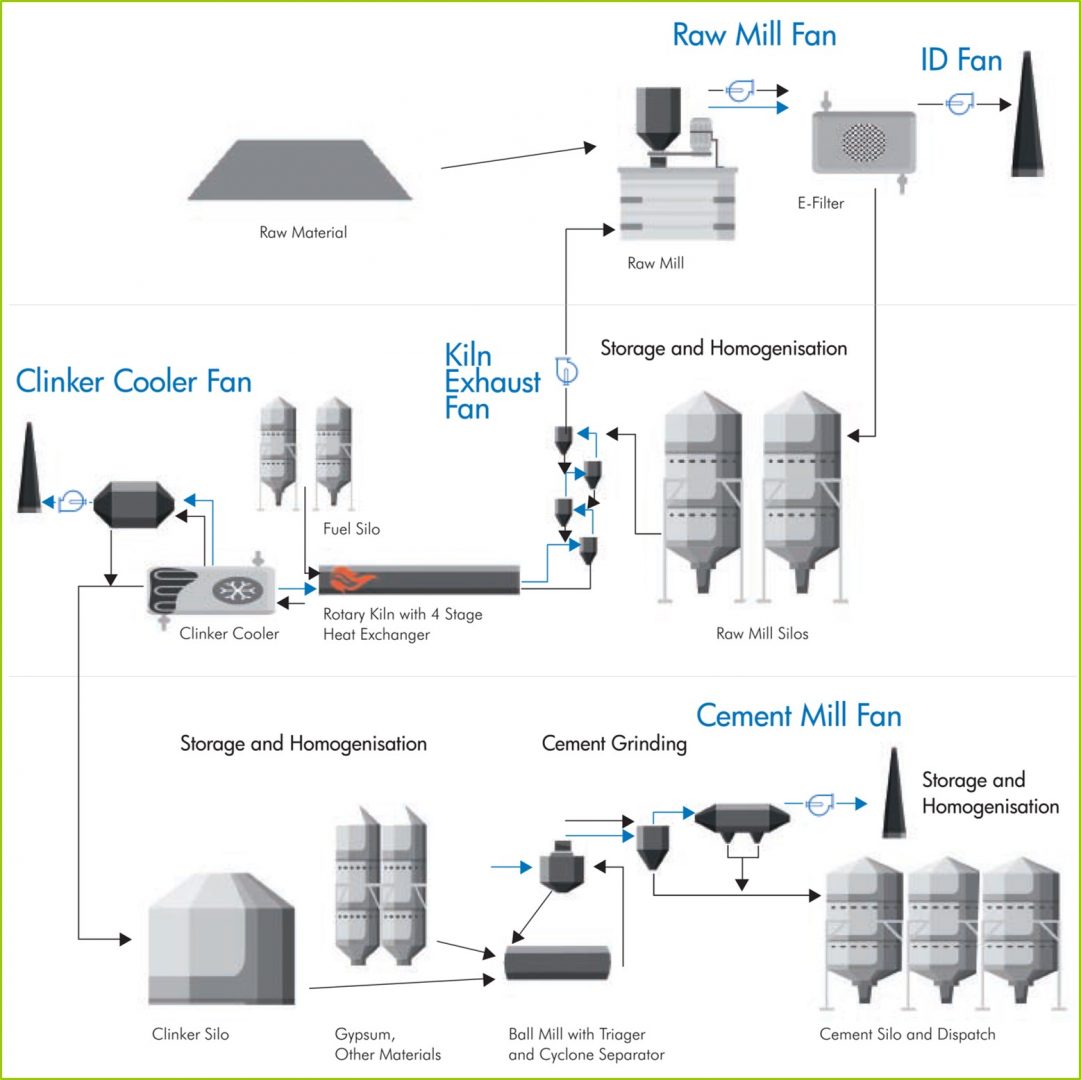

Fig. 1. A typical production line of a cement plant

Destruction of the induced draft fan and restoration design

-After a certain time working under unstable load changes and heat shock, high speed rotating elements can be destructed caused by several impacts in which the severe parameters are abnormal thermal expansion and mechanical creep damage.

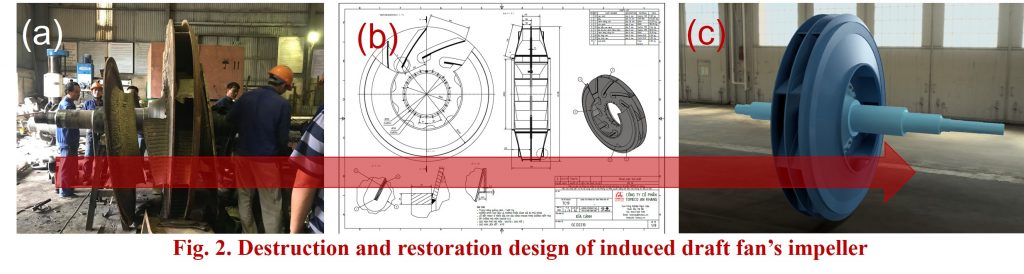

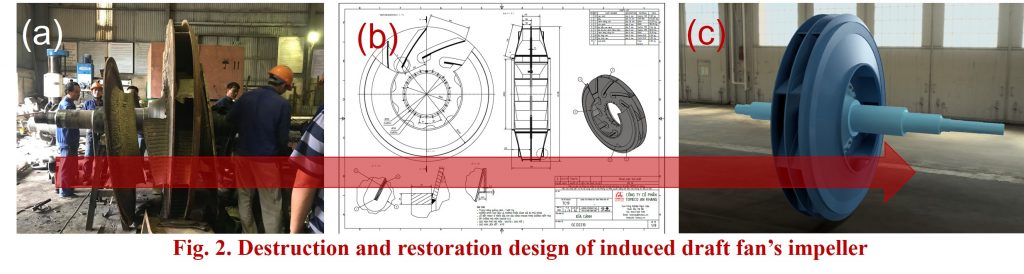

-There are various kind of destruction of the rotating elements and in general all the structures of these elements are often terrible deformed as seen in Fig. 2a. Thus, out of using spare parts, restoration manufacturing should be applied to keep the whole plant operation under control.

-In case of restoration design, gas flow hydrodynamics and structure deformation should be re-analyzed. In this work, such a design work is carried out for the restoration of an induced draft fan working under the operating condition of (1) capacity: 280000 m3/h; (2) total pressure: 7200 Pa; (3) operating temperature: 350 oC (max: 450 oC); (4) impeller speed: 1300 rpm to keep the clinker production of the plant at around 2000 tons per day (see Fig. 2b,c).

Finite element simulation and thermal stress analysis

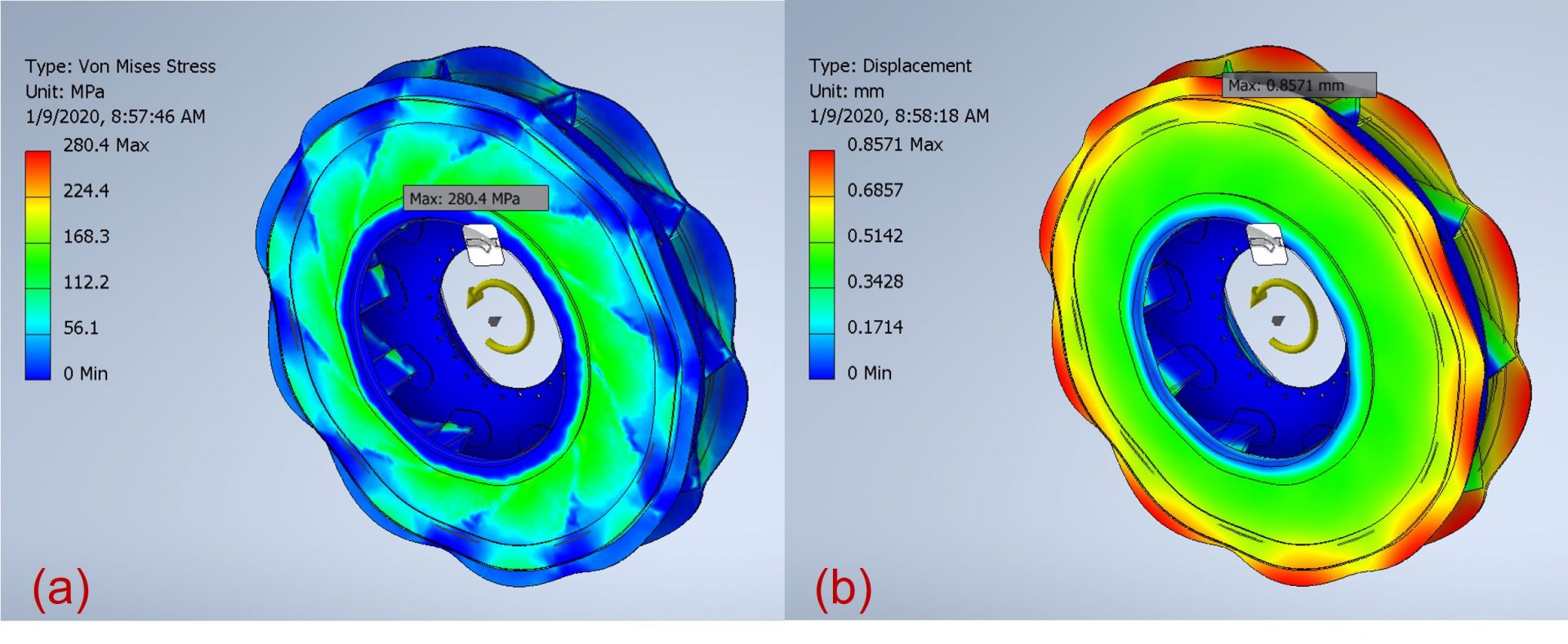

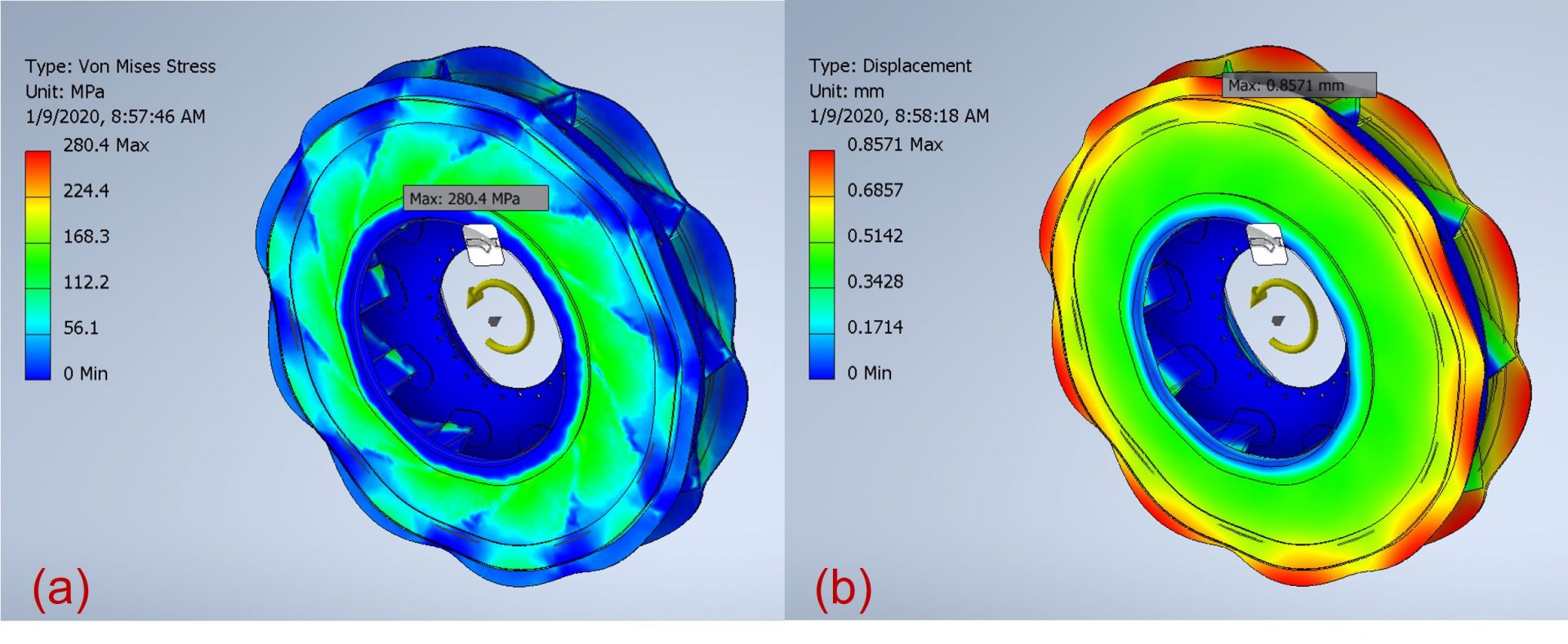

Fig. 3. Distribution of (a) Von Mises stress and (b) displacement at the speed of 1300 rpm

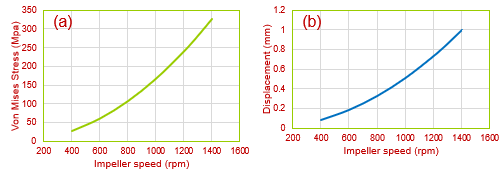

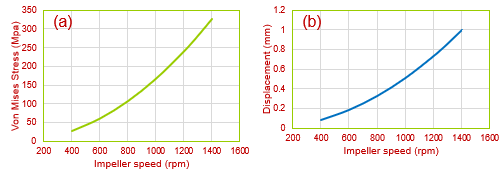

Fig. 4. Effects of impeller speed on (a) Maximum stress and (b) Maximum displacement

Conclusions

1.Restoration of a heavy-duty induced draft fan working at high temperature under dust laden and wear/abrasion effects is conducted by means of process design, hydrodynamics and FEA.

2.Numerical results obtained from the FEA is used to select a proper MOC for the impeller manufacturing.

3.Mechanical behavior of high strength steel at different temperatures is applied to evaluate the feasible heat resistant MOC and operation of the induced draft fan working under high temperature condition in cement industry.

TOMECO MECHANIC-ELECTRICAL JOINT STOCK COMPANY

www.tomeco.vn Email: toancau@tomeco.vn

Fig. 5. Strength of the selected MOC at different temperature and the real restoration impeller

References

[1] Maraveas C , Fasoulakis Z C , Tsavdaridis K D. Mechanical properties of high and very high steel at elevated temperatures and after cooling down. Fire Science Reviews 2017;6(3):1–13. [2] Kodur V , Dwaikat M , Fike R. High-temperature properties of steel for fire resistance modeling of structures. Journal of materials in civil engineering, ASCE 2010;22(5):423–434.A study of

Thanh Le Quy – R&D Department, TOMECO Mechanic-Electrical Joint Stock Company, 53 Nguyen Xien, Hanoi, Vietnam

Dan Nguyen Duc, Thai Tran Luong – Technical and Design Department, TOMECO AN KHANG Joint Stock Company, Ngoc Liep Industrial Zone, Quoc Oai, Hanoi, Vietnam

Tiếng Việt

Tiếng Việt English

English