APPLICATIONS

Applying the same principles to the ventilation system using axial jet fans, the jet fan centrifugal fans give the user the space-saving capability and the amount of equipment that needs to be installed. Thinness and strength in operation.

With a thrust of up to 100N, the floor area of the parking lot effected by each centrifugal jet fan increased significantly compared to the axial jet fan.

Starting from the above advantages, these application systems typically require fewer devices, thereby reducing associated costs such as wire investment and control systems, installation costs, and shipping costs. maintenance and maintenance.

In addition, centrifugal fan fans can work particularly well in low-rise underground parking lots and have close-fitting beams because of their overall length and thickness. with axial jet fans.

PROPERTIES

General introduction

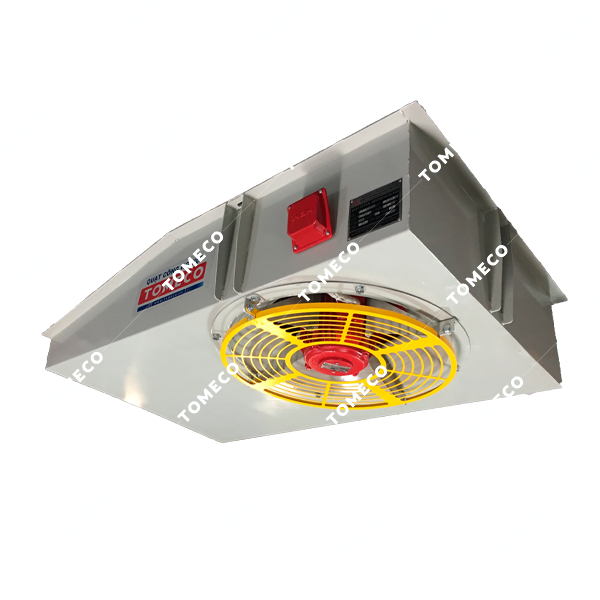

Jet fans centrifugal fans designed and manufactured by TOMECO are the most modern and most modern line of application in the world.

Jet centrifugal fans are used to meet the ventilation and air conditioning needs of parking lots and underground service areas. Jet fans centrifugally reduce emissions in the parking lot under normal conditions and assist smoke extraction in the event of a fire incident by rapidly pushing exhaust and smoke to the suction position in the parking lot.

Jet fans centrifuges traffic tunnel ventilation technologies to eliminate costly and complex pipeline systems. Compared with traditional ventilation systems using pipes, jet centrifugal fans help save space, reduce operating costs, reduce noise and make parking more bright and modern.

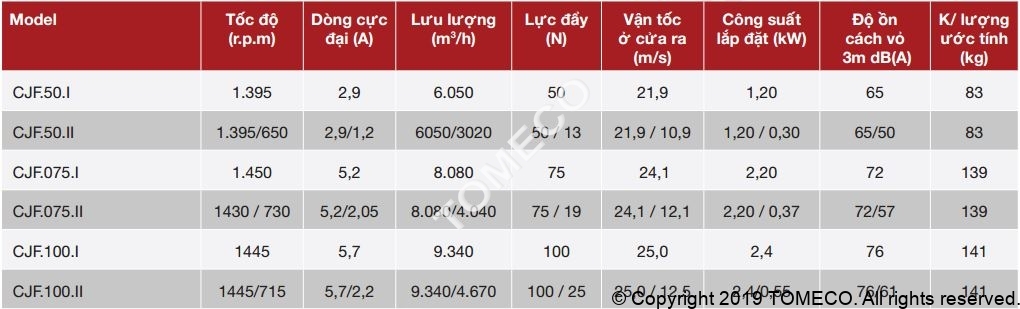

3 different sizes with diameter range from 500 to 1,000mm.

Maximum thrust is up to 100N.

Resistance to 150/200 / 250ºC within 1 / 1.5 / 2h depending on application requirements.

SPECIFICATIONS

Exquisite design with remarkable thinness: the overall thickness of the fan can be as thin as 282.5mm, especially suitable for underground parking lots of limited height.

Reliable operation: aerodynamic design is thoroughly researched and tested to certify heat resistance under 300ºC conditions within one hour.

Robust structure – high durability: the fan is made from high quality steel plate with surface treatment and high-grade static coating.

Savings on maintenance, maintenance costs: with the advantage of eliminating the complex and complex piping system.

Increase visibility for CCTV systems: Helps the surveillance camera system operate more efficiently than traditional piping systems.

Energy saving: Centrifugal treads with backward curved motors with outstanding dynamic performance, up to 80% high, reduce energy consumption and reduce operating costs.

CFD simulation of the jet fan system in the basement.

Great thrust – with great thrust, each fan can effectively work for a wider area. This also means that the centrifugal fan application system requires less equipment than conventional axial jet fans. In addition, the cost of auxiliary items such as wiring, control equipment, installation, operation and maintenance are also significantly reduced.

Flexible speed options – fans can be fitted with one-speed, two-speed or in-line motors controlled via an inverter inverter to save energy according to each application.

Low noise – smooth operation, friendly environment, noise standard European.

Tiếng Việt

Tiếng Việt English

English